Πορτ Φέντερς Μακρά διάρκεια ζωής Ελαφριά κατασκευή Εύκολη εγκατάσταση

Περιγραφή

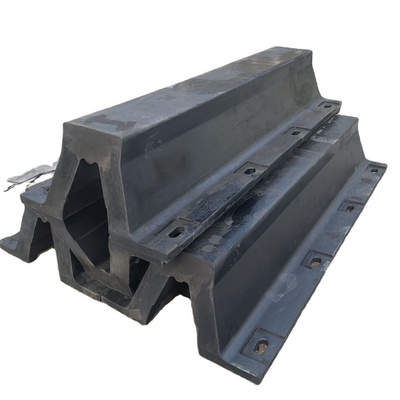

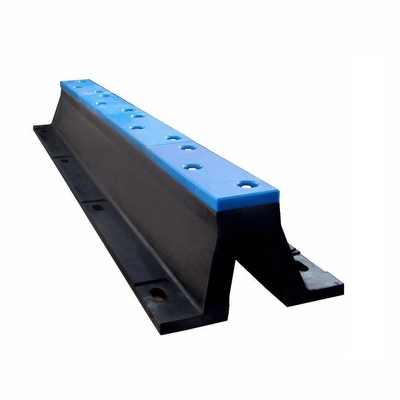

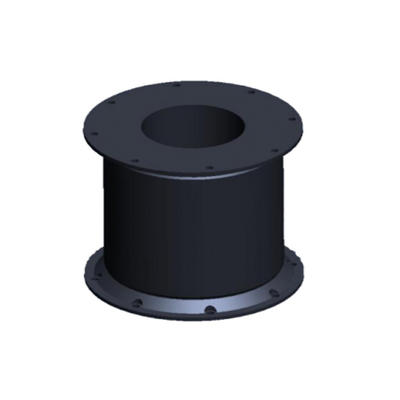

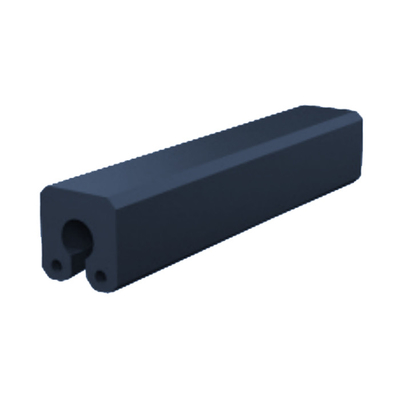

Το Floating Foam Fender είναι ένα θαλάσσιο φεντερ υψηλών επιδόσεων που έχει σχεδιαστεί ειδικά για ακραίες κλιματικές συνθήκες και εφαρμογές μηχανικής υπεράκτιας θάλασσας.Κατασκευασμένα από αφρό πολυαιθυλενίου κλειστών κυττάρων υψηλής πυκνότητας, περιβαλλόμενο με πολυουρεθάνιο θαλάσσιου τύπου ή συνθετικό καουτσούκ, ο φτέρνας παρέχει ανώτερη απορρόφηση ενέργειας, εξαιρετική αντοχή και σταθερή επιβίωση, ακόμη και σε σκληρό καιρό, συνθήκες παγώματος ή έντονα περιβάλλοντα υπεριώδους ακτινοβολίας.

Σχεδιασμένο για να αντέχει σε βαριές επιπτώσεις αγκυροβολίας και συνεχείς δυνάμεις κύματος και παλίρροιας, το φτέρνισμα διατηρεί χαμηλή δύναμη αντίδρασης για την προστασία τόσο των πλοίων όσο και των δομών.Το αβυθιστό σχεδιασμό του εξαλείφει τον κίνδυνο αποτυχίας σε κρίσιμες υπεράκτιες ή ακραίες περιβαλλοντικές εργασίεςΗ εξωτερική επικάλυψη παρέχει αντοχή σε υπεριώδη ακτινοβολία, φθορά και διάβρωση, εξασφαλίζοντας μακροχρόνια απόδοση και ελάχιστη συντήρηση.

Διαθέσιμο σε διαμέτρους που κυμαίνονται από 1.000 mm έως 4.500 mm και μήκους έως 5 m, το σκάφος μπορεί να φιλοξενήσει σκάφη από μικρά σκάφη υπηρεσίας έως 60.000 φορτηγά και υπεράκτια σκάφη.Η πλωτή και προσαρμόσιμη σχεδίασή του του επιτρέπει να λειτουργεί αποτελεσματικά σε περιοχές με παλίρροιαΤο κτίριο είναι ιδανικό για υπεράκτιες πλατφόρμες, αιολικά πάρκα και εκτεθειμένες λιμενικές εγκαταστάσεις.ο προστατευτής βελτιώνει σημαντικά την ασφάλεια λειτουργίας και μειώνει το συνολικό κόστος συντήρησης.

Μελέτη περιπτώσεων ∆ιαβρύχιο αιολικό πάρκο

Σε ένα υπεράκτιο αιολικό πάρκο του Βόρειου Ατλαντικού, η εγκατάσταση των πλωτών φουσκωτών ελατηρίων προστάτευσε πλοία υπηρεσίας και εφοδιασμού που κυμαίνονται από 2.000 έως 10.000 DWT.Τα πλοία υπέστησαν γρατζουνιές στο κύτος και φθορά στην αγκυροβόληση της πλατφόρμας κατά τη διάρκεια της αγκυροβολίας σε μεγάλα κύματα και ισχυρούς ανέμους.

Η εγκατάσταση φτερών με διάμετρο 1.500 mm και μήκος 3 m βελτίωσε την ασφάλεια της αποβάθρας, μείωσε τη συντήρηση τόσο των σκαφών όσο και των σημείων αγκυρώσεως της πλατφόρμας,και διατήρησε σταθερή απόδοση σε θερμοκρασίες κάτω του μηδενικούΗ ανατροφοδότηση από τους χειριστές επιβεβαίωσε ότι οι προφυλακτήρες παρείχαν αξιόπιστη προστασία και λειτουργική αποτελεσματικότητα,καθιστώντας τους κατάλληλους για αναπαραγωγή σε άλλες θέσεις αποβάθρας υπεράκτιας υπηρεσίας.

Προδιαγραφές

| Ονομασία του προϊόντος |

Ανεμόπνευμα |

| Τύπος προϊόντος |

Κλειστοκύτταρο γεμάτο αφρό πλωτό φεντερ |

| Βασικό υλικό |

Πολυαιθυλένιο υψηλής πυκνότητας με κλειστά κύτταρα |

| Εξωτερικό δέρμα |

Ενεργοποιημένο πολυουρεθάνιο ή ελαστομερές καουτσούκ |

| Δυνατότητα επιβίβασης |

Αβύθιστη, θετική επιβίωση |

| Απορρόφηση ενέργειας |

Υψηλή απορρόφηση ενέργειας με χαμηλή δύναμη αντίδρασης |

| Ανθεκτικότητα στο καιρό |

Ανθεκτικό στις ΗΠ, στο Νερό της Θάλασσας και στην Γήρανση |

| Εγκατάσταση |

Εγκατάσταση αλυσίδας ή στήριξης, προσαρμόσιμη |

| Ζωή υπηρεσίας |

15·20 έτη υπό κανονικές συνθήκες λειτουργίας |

|

Διάμετρος x μήκος

|

Απορρόφηση ενέργειας 60% comp

|

Δύναμη αντίδρασης στο 60% comp

|

Περίπου βάρος

|

|

(μμ)

|

(kNm)

|

(kN)

|

(kg)

|

|

300 x 1000

|

3.8

|

54

|

11

|

|

500 x 1000

|

10.6

|

91

|

41

|

|

600 x 1000

|

15.3

|

109

|

49

|

|

600 x 1000

|

18.3

|

131

|

55

|

|

700 x 1500

|

31

|

191

|

85

|

|

750 x 1500

|

36

|

204

|

89

|

|

900 x 1800

|

62

|

294

|

140

|

|

1000 x 1500

|

64

|

272

|

125

|

|

1000 x 2000

|

85

|

363

|

170

|

|

1200 x 2000

|

122

|

436

|

275

|

|

1200 x 2400

|

146

|

523

|

365

|

|

1250 x 2000

|

132

|

454

|

353

|

|

1250 x 2500

|

165

|

567

|

410

|

|

1500 x 3000

|

286

|

817

|

570

|

|

1500 x 4000

|

381

|

1089

|

720

|

|

1700 x 3000

|

367

|

926

|

700

|

|

1700 x 3500

|

428

|

1080

|

780

|

|

1800 x 3000

|

412

|

980

|

850

|

|

1800 x 3600

|

494

|

1176

|

965

|

|

2000 x 3000

|

508

|

1089

|

965

|

|

2000 x 3500

|

593

|

1271

|

1100

|

|

2000 x 4000

|

678

|

1452

|

1220

|

|

2400 x 4000

|

976

|

1743

|

1720

|

|

2400 x 4800

|

1171

|

2091

|

2140

|

|

2500 x 4000

|

1059

|

1815

|

1865

|

|

2500 x 5000

|

1324

|

2269

|

2500

|

|

2500 x 5500

|

1456

|

2496

|

2675

|

|

2700 x 5400

|

1668

|

2647

|

2865

|

|

3000 x 5000

|

1925

|

2750

|

3200

|

|

3000 x 6000

|

2287

|

3268

|

3740

|

|

3300 x 6500

|

2998

|

3894

|

4735

|

|

3600 x 7200

|

3953

|

4706

|

5800

|

|

4000 x 8000

|

4522

|

5809

|

8700

|

|

4200 x 8400

|

6277

|

6405

|

10000

|

|

4500 x 9000

|

7720

|

7353

|

10700

|

Χαρακτηριστικά

Εξαιρετική Αντίσταση στο Κλίμα

Ο πυρήνας αφρού και η εξωτερική επικάλυψη είναι σχεδιασμένοι για να αντέχουν θερμοκρασίες από -40 °C έως +80 °C, έκθεση σε υπεριώδη ακτινοβολία, πάγο και βαριά βροχοπτώσεις χωρίς να χάνουν τη δομική ακεραιότητα ή την απόρροια ενέργειας.

Υψηλή απορρόφηση και χαμηλή δύναμη αντίδρασης

Ο πυρήνας αφρού υψηλής πυκνότητας εξαλείφει ομοιόμορφα την ενέργεια της πρόσκρουσης, μειώνοντας την πίεση κορυφής στα κύτη και τις ανοικτές δομές.Αυτό επιτρέπει την ασφαλή αγκυροβόληση βαρέων υπεράκτιων πλοίων και πλοίων μεταφοράς εξοπλισμού χωρίς υπερβολική δύναμη στα σημεία αγκυρώσεως.

Μακροχρόνια αντοχή και αντοχή στη διάβρωση

Το εξωτερικό στρώμα πολυουρεθάνου παρέχει εξαιρετική αντοχή στη διάβρωση από το αλμυρό νερό, τη θαλάσσια ανάπτυξη και την έκθεση σε χημικές ουσίες, εξασφαλίζοντας διάρκεια ζωής 15-20 ετών ακόμη και σε ακραίες θαλάσσιες συνθήκες.

Πλωτή και Προσαρμοστική Σχεδίαση

Ο προστατευτής προσαρμόζεται αυτόματα στις διακυμάνσεις της στάθμης του νερού και την κίνηση των κυμάτων, διατηρώντας συνεχή προστατευτική κάλυψη, η οποία είναι κρίσιμη για τις υπεράκτιες πλατφόρμες, τα εκτεθειμένα λιμάνια,και πλωτά πόντον.

Εφαρμογές

Ακτές αιολικές εγκαταστάσεις και πετρελαϊκές πλατφόρμες

Προστατεύει τα πλοία υπηρεσίας, τα πλοία εφοδιασμού και τα σκάφη πληρώματος από τις επιπτώσεις των κυμάτων, τις αλλαγές της παλίρροιας και τον σκληρό καιρό.

Εκτίθενται λιμένες και βιομηχανικές εγκαταστάσεις

Παρέχει μείωση των συγκρούσεων και προστασία του κύτους σε λιμάνια που αντιμετωπίζουν ισχυρά ρεύματα, ισχυρούς ανέμους ή ακραίες διακυμάνσεις θερμοκρασίας.

Προσωρινές λιμάνιες θέσεις και εγκαταστάσεις κατασκευής

Κατάλληλο για πλωτές πλατφόρμες, αγκυροβολημένες αποβάθρες και ανοικτές περιοχές κατασκευής, εξασφαλίζοντας ασφαλείς λειτουργίες υπό απαιτητικές περιβαλλοντικές συνθήκες.

Γιατί να επιλέξετε την Hongruntong Marine

Εμπειρογνωμοσύνη στη μηχανική ακραίων περιβαλλοντικών συνθηκών

Η Hongruntong Marine παρέχει λύσεις θαλάσσιων φτέρνων για υπεράκτιες και ακραίες καιρικές συνθήκες, ενσωματώνοντας δοκιμασμένα υλικά και σχέδια για να εξασφαλίσει συνεπή προστασία.

Προσαρμοσμένες Λύσεις για Δυσκολείς Προϋποθέσεις

Παρέχουμε εξατομικευμένες διαστάσεις, πυκνότητες αφρού και υλικά εξωτερικής επικάλυψης για να ανταποκριθούμε στις λειτουργικές απαιτήσεις σε ισχυρούς ανέμους, θερμοκρασίες κατάψυξης ή σε ισχυρές περιοχές υπεριώδους ακτινοβολίας.

Μακροζωία και Αξιόπιστη

Οι προστατευτές μας κατασκευάζονται για να διατηρούν την απορρόφηση ενέργειας και την επιβίωση για δεκαετίες, ελαχιστοποιώντας το κόστος αντικατάστασης και συντήρησης, ακόμη και σε ακραίες συνθήκες ανοικτής θάλασσας.

Πλήρης υποστήριξη του κύκλου ζωής

Η Hongruntong Marine παρέχει καθοδήγηση εγκατάστασης, αξιολόγηση της απόδοσης και τεχνική συμβουλευτική για να εξασφαλιστεί η συνεχιζόμενη αξιοπιστία και η βέλτιστη ασφάλεια για τις εγκαταστάσεις ανοικτής θάλασσας και εκτεθειμένες.

Γενικές ερωτήσεις

1Μπορεί ο φτέρνας να αντεπεξέλθει σε χαμηλές θερμοκρασίες και πάγο;

Ναι, ο πυρήνας από αφρό και η επικάλυψη από πολυουρεθάνιο είναι σχεδιασμένοι για να παραμένουν ευέλικτοι και λειτουργικοί σε θερμοκρασίες τόσο χαμηλές όσο -40°C, εξασφαλίζοντας ασφαλή αγκυροβόληση σε ψυχρά κλίματα.

2Είναι κατάλληλο για υψηλές κυματικές και παλίρροια συνθήκες;

Ο σχεδιασμός επιπλέων επιτρέπει την αυτόματη προσαρμογή στις αλλαγές της παλίρροιας και των κυμάτων, διατηρώντας συνεπή προστασία του κύτους.

3- Ποια συντήρηση απαιτείται για χρήση στην ανοικτή θάλασσα;

Συνιστάται περιοδική επιθεώρηση για να ελέγξετε την ακραία συσκότιση, αλλά ο αδιάβροχος πυρήνας αφρού εξασφαλίζει συνεχή λειτουργικότητα.

4Μπορεί η προστατευτική συσκευή να προστατεύσει μεγάλα πλοία υπεράκτιας υπηρεσίας;

Ναι, είναι κατάλληλο για πλοία έως 60.000 DWT, παρέχοντας εξαιρετική απορρόφηση των συγκρούσεων και χαμηλή δύναμη αντίδρασης στις δομές του πλοίου και των λιμάνων.

5Ποια είναι η αναμενόμενη διάρκεια ζωής σε δύσκολες συνθήκες υπεράκτιας αλιείας;

Με τη σωστή επιλογή, 15-20 χρόνια, ακόμα και με έκθεση σε αλμυρό νερό, ισχυρή υπεριώδη ακτινοβολία, θερμοκρασίες κατάψυξης και βαριά μηχανική επίδραση.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!