Βιομηχανικό Ελαστικό Προφυλακτήρα Ανώτερη Αντοχή στη Φθορά Σταθερότητα UV και Ελάχιστη Συντήρηση

Περιγραφή

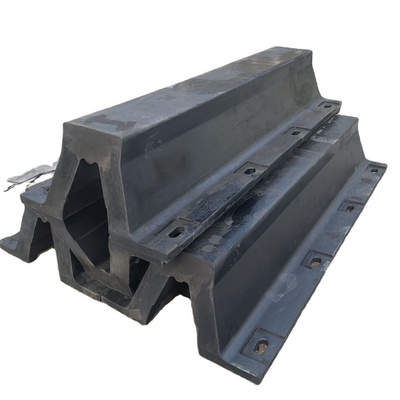

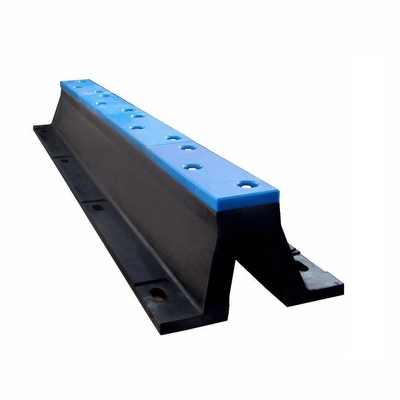

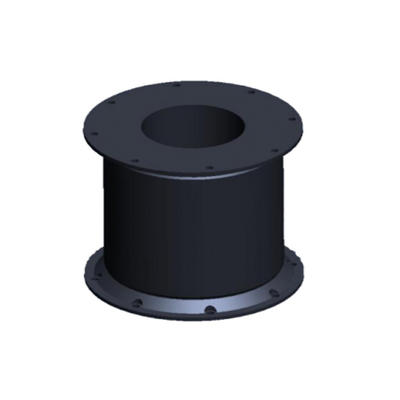

Ο Προφυλακτήρας Τύπου D από την Hongruntong Marine είναι ένα προηγμένο σύστημα θαλάσσιας προστασίας σχεδιασμένο για κατασκευές που εκτίθενται σε συνεχή κυματισμό, αλλαγές παλίρροιας και επαφή με σκάφη. Παρέχει ένα αξιόπιστο ρυθμιστικό μέσο μεταξύ των σκαφών και των σταθερών εγκαταστάσεων, όπως οι προβλήτες γεφυρών, οι πλωτές αποβάθρες και οι υπεράκτιες πλατφόρμες, όπου η αντοχή στην κρούση και η περιβαλλοντική ανθεκτικότητα είναι κρίσιμες.

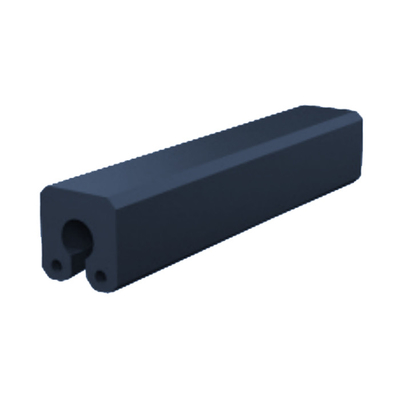

Το διακριτικό D-shaped προφίλ του προφυλακτήρα επιτρέπει την αποτελεσματική απορρόφηση ενέργειας διατηρώντας παράλληλα τη δομική σταθερότητα. Η κοίλη γεωμετρία του πυρήνα εξισορροπεί την ελαστικότητα και την αντοχή, προσφέροντας σταθερή απόδοση υπό συνθήκες συμπίεσης. Κάθε προφυλακτήρας εξωθείται από μια ειδικά σχεδιασμένη ένωση θαλάσσιου βαθμού από καουτσούκ, σχεδιασμένη να αντιστέκεται στο όζον, την υπεριώδη ακτινοβολία, το θαλασσινό νερό και τις διακυμάνσεις της θερμοκρασίας.

Μελέτη περίπτωσης – Προστασία υπεράκτιας γέφυρας, Νορβηγία

Μια παράκτια γέφυρα στη δυτική Νορβηγία αντιμετώπιζε συχνές μικρές συγκρούσεις από σκάφη εξυπηρέτησης και φορτηγίδες συντήρησης, ειδικά κατά τη διάρκεια έντονων παλίρροιας και χειμερινών καταιγίδων. Οι προηγούμενοι κυλινδρικοί προφυλακτήρες υποβαθμίστηκαν γρήγορα, χάνοντας την ελαστικότητα και σκίζοντας μετά από δύο χειμώνες. Η Hongruntong Marine παρείχε έναν προσαρμοσμένο προφυλακτήρα τύπου D ανθεκτικό στο κρύο, χρησιμοποιώντας ένα μείγμα ελαστομερούς χαμηλής θερμοκρασίας με ενισχυμένη αντοχή στο σχίσιμο και πρόσθετα κατά του όζοντος.

Εγκατεστημένοι το 2020 κατά μήκος των προσώπων της προβλήτας, οι προφυλακτήρες τύπου D έχουν υπομείνει έκτοτε συνεχή έκθεση σε παγωμένο θαλασσινό νερό, τριβή πάγου και μηχανική καταπόνηση. Μετά από τέσσερα χρόνια, οι εκθέσεις επιθεώρησης έδειξαν καμία δομική ζημιά, μείωση άνω του 50% στο φορτίο κρούσης στις επιφάνειες της προβλήτας και καμία απώλεια απόδοσης ακόμη και μετά από θερμοκρασίες κάτω από -25°C. Η τοπική ναυτιλιακή αρχή αναγνώρισε το σύστημα ως μια οικονομικά αποδοτική λύση χαμηλής συντήρησης για την προστασία των παράκτιων γεφυρών.

Αυτό το έργο απέδειξε πώς οι προφυλακτήρες τύπου D της Hongruntong αποδίδουν σε ακραίες συνθήκες—διατηρώντας την ευελιξία, την πρόσφυση και την απορρόφηση κραδασμών σε σκληρά κλίματα και διαβρωτικά θαλάσσια περιβάλλοντα.

Προδιαγραφές

| Όνομα προϊόντος |

Προφυλακτήρες τύπου D |

| Επωνυμία |

Hongruntong Marine |

| Υλικό |

Υψηλής απόδοσης φυσικό καουτσούκ |

| Χρώμα |

Μαύρο και Απαιτήσεις Πελατών |

| Τύπος |

Σταθεροί ελαστικοί προφυλακτήρες D |

| Πρότυπο |

HGT2866-2016, PIANC2002 |

| Απορρόφηση ενέργειας |

147kN έως 920kN |

| Δύναμη αντίδρασης |

5.1KN-M έως 64KN-M |

| Εφαρμογή |

Λιμάνι, αποβάθρα, αποβάθρα κ.λπ. |

| A |

B |

C |

D |

E |

F |

H |

K |

| [mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

| 70 |

30 |

15 |

30 |

45 |

80 |

90 - 130 |

200 - 300 |

| 100 |

45 |

15 |

30 |

50 |

100 |

90 - 130 |

200 - 300 |

| 125 |

60 |

20 |

40 |

60 |

125 |

110 - 150 |

250 - 300 |

| 150 |

75 |

20 |

40 |

75 |

150 |

110 - 150 |

250 - 300 |

| 150 |

80 |

25 |

50 |

100 |

200 |

130 - 180 |

300 - 400 |

| 200 |

100 |

25 |

50 |

100 |

200 |

130 - 180 |

300 - 400 |

| 200 |

100 |

30 |

60 |

125 |

250 |

140 - 200 |

350 - 450 |

| 250 |

125 |

30 |

60 |

125 |

250 |

140 - 200 |

350 - 450 |

| 300 |

150 |

30 |

60 |

150 |

300 |

140 - 200 |

350 - 450 |

| 350 |

175 |

35 |

75 |

175 |

350 |

140 - 200 |

350 - 450 |

| 380 |

190 |

35 |

75 |

190 |

380 |

140 - 200 |

350 - 450 |

| 300 |

150 |

35 |

75 |

175 |

400 |

140 - 200 |

350 - 450 |

| 400 |

200 |

35 |

75 |

200 |

400 |

140 - 200 |

350 - 450 |

| 500 |

250 |

45 |

90 |

250 |

500 |

160 - 230 |

400 - 500 |

| *Σημείωση: Άλλα μεγέθη μπορούν να προσαρμοστούν σύμφωνα με τις απαιτήσεις. |

| A |

B |

C |

D |

E |

F |

G |

H |

K |

| [mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

| 100 |

25 |

10 |

30 |

15 |

100 |

50 |

90 - 130 |

200 - 300 |

| 150 |

30 |

12 |

65 |

20 |

150 |

75 |

110 - 150 |

250 - 350 |

| 200 |

45 |

15 |

75 |

25 |

200 |

100 |

130 - 180 |

300 - 400 |

| 250 |

50 |

20 |

100 |

30 |

250 |

125 |

140 - 200 |

350 - 450 |

| 300 |

60 |

25 |

125 |

30 |

300 |

150 |

140 - 200 |

350 - 450 |

| 350 |

70 |

25 |

150 |

35 |

350 |

175 |

140 - 200 |

350 - 450 |

| 400 |

80 |

30 |

175 |

35 |

400 |

200 |

140 - 200 |

350 - 450 |

| 400 |

80 |

30 |

200 |

35 |

400 |

200 |

140 - 200 |

350 - 450 |

| 500 |

100 |

30 |

250 |

35 |

500 |

250 |

140 - 200 |

350 - 450 |

Χαρακτηριστικά

Αντοχή σε ακραίες θερμοκρασίες

Σχεδιασμένο με προηγμένα μείγματα πολυμερών που διατηρούν την ελαστικότητα και την αντοχή σε εφελκυσμό από -40°C έως +80°C. Ιδανικό για βόρεια κλίματα ή τροπικές υπεράκτιες πλατφόρμες με θερμική κυκλοφορία.

Ενισχυμένη προστασία από τη διάβρωση και την υπεριώδη ακτινοβολία

Η ένωση του προφυλακτήρα περιέχει παράγοντες κατά της γήρανσης, σταθεροποιητές UV και συστατικά κατά του όζοντος για να αντιστέκεται στο ηλιακό φως, το θαλασσινό νερό και τη χημική υποβάθμιση, εξασφαλίζοντας μεγάλη διάρκεια ζωής ακόμη και σε εκτεθειμένα παράκτια περιβάλλοντα.

Βελτιστοποιημένος σχεδιασμός κοίλου πυρήνα για υψηλή απορρόφηση ενέργειας

Η εσωτερική δομή κατανέμει ομοιόμορφα τα φορτία συμπίεσης, παρέχοντας ανώτερη απορρόφηση ενέργειας κρούσης και γρήγορη ανάκαμψη. Αυτό μειώνει τη μεταφορά τάσης στις δομές της γέφυρας ή της πλατφόρμας.

Ευελιξία προσαρμοσμένης τοποθέτησης

Προσαρμόσιμο σε εγκαταστάσεις από σκυρόδεμα, χάλυβα ή πλωτές αποβάθρες χρησιμοποιώντας διάφορα συστήματα στερέωσης—μπουλόνια, χαλύβδινα πλαίσια ή ένθετα καναλιών U. Ο αρθρωτός σχεδιασμός επιτρέπει γρήγορη εγκατάσταση και αντικατάσταση χωρίς εκτεταμένο χρόνο διακοπής.

Εφαρμογές

Προβλήτες γεφυρών και παράκτιες κατασκευές

Προστατεύει τις κολώνες της γέφυρας από συγκρούσεις σκαφών και μειώνει το κόστος συντήρησης που προκαλείται από επαναλαμβανόμενες κρούσεις και δυνάμεις κυμάτων.

Πλωτές αποβάθρες και θαλάσσιες πλατφόρμες

Προσφέρει ανθεκτική πλευρική προστασία για πλωτές κατασκευές που εκτίθενται σε παλιρροϊκή και κυματική κίνηση, διατηρώντας σταθερή απόδοση κρούσης.

Εγκαταστάσεις πετρελαίου και υπεράκτιες εγκαταστάσεις

Παρέχει κρίσιμη απορρόφηση κραδασμών από το κύτος στην κατασκευή σε υπεράκτια περιβάλλοντα με υψηλή διάβρωση και δυναμικές συνθήκες φόρτισης.

Γιατί να επιλέξετε την Hongruntong Marine

Προηγμένη μηχανική θαλάσσιων υλικών

Hongruntong Marine χρησιμοποιεί ιδιόκτητη τεχνολογία ανάμειξης καουτσούκ για την ενίσχυση της αντοχής, της ελαστικότητας και της ανθεκτικότητας στη θερμοκρασία. Κάθε παρτίδα υποβάλλεται σε ακριβείς δοκιμές για σκληρότητα, ιδιότητες εφελκυσμού και ανάκαμψη συμπίεσης.

Δεκαετίες εμπειρίας στην υπεράκτια και πολιτική ναυτιλία

Με πάνω από 20 χρόνια προμήθειας λύσεων προφυλακτήρων σε υπεράκτια, λιμενικά και γεφυρικά έργα, οι μηχανικοί της Hongruntong σχεδιάζουν προφυλακτήρες που πληρούν αυστηρά διεθνή πρότυπα, συμπεριλαμβανομένων των κατευθυντήριων γραμμών ISO 17357 και PIANC.

Επαλήθευση και δοκιμή απόδοσης

Όλοι οι προφυλακτήρες υποβάλλονται σε δοκιμές φορτίου κρούσης, ανάλυση επιταχυνόμενης γήρανσης και αξιολόγηση διάβρωσης με ψεκασμό αλατιού για να εξασφαλιστεί η μέγιστη διάρκεια ζωής και η μηχανική ακεραιότητα σε σκληρά θαλάσσια περιβάλλοντα.

Προσαρμοσμένες μηχανικές λύσεις και παγκόσμια υποστήριξη

Κάθε έργο υποστηρίζεται από τρισδιάστατη μοντελοποίηση, προσαρμοσμένο σχεδιασμό τοποθέτησης και σχεδιασμό logistics. Οι παγκόσμιοι πελάτες επωφελούνται από την επίβλεψη εγκατάστασης, την παρακολούθηση απόδοσης και την υποστήριξη μακροχρόνιας συντήρησης.

Συχνές ερωτήσεις

1. Είναι οι προφυλακτήρες τύπου D κατάλληλοι για κρύα ή παγωμένα νερά;

Ναι, οι συνθέσεις μας ανθεκτικές στο κρύο παραμένουν εύκαμπτες και απορροφητικές κρούσεων ακόμη και στους -40°C.

2. Μπορούν οι προφυλακτήρες να χρησιμοποιηθούν για υποβρύχια εγκατάσταση;

Μπορούν να λειτουργήσουν μερικώς βυθισμένοι. Οι ενώσεις καουτσούκ αντιστέκονται στην υποβάθμιση του θαλασσινού νερού και την πρόσφυση θαλάσσιας ανάπτυξης.

3. Ποιες επιλογές τοποθέτησης είναι διαθέσιμες για εφαρμογές γεφυρών;

Προσφέρουμε βιδωτές χαλύβδινες πλάκες, βάσεις καναλιών U ή ενισχυμένα στηρίγματα προσαρμοσμένα στη δομική γεωμετρία.

4. Απαιτούν οι προφυλακτήρες ειδικές επιστρώσεις ή βαφή;

Δεν απαιτείται επίστρωση. Το ίδιο το καουτσούκ περιέχει σταθεροποιητές κατά της υπεριώδους ακτινοβολίας και κατά του όζοντος για προστασία της επιφάνειας.

5. Πόση είναι η αναμενόμενη διάρκεια ζωής σε υπεράκτια περιβάλλοντα;

Τυπικά 10–15 χρόνια ανάλογα με την έκθεση σε κύματα, τη συχνότητα των σκαφών και τις πρακτικές συντήρησης.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!