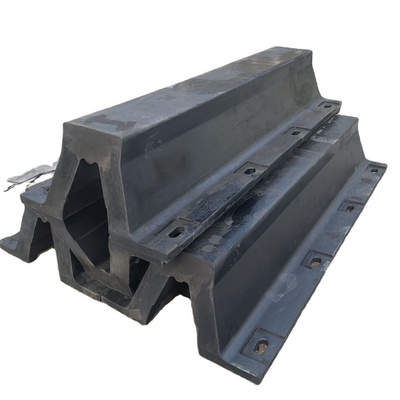

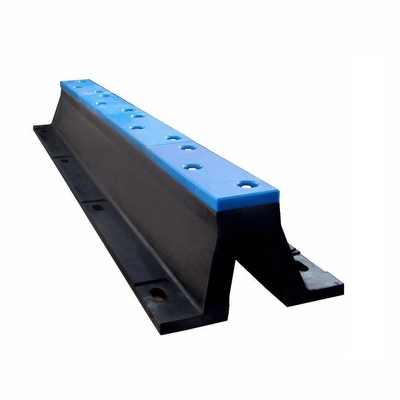

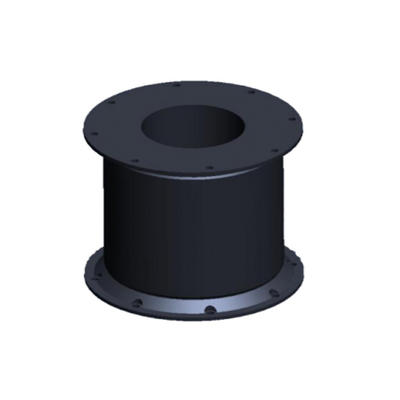

600×1200mm Marine Fender Απορρόφηση κρουσμάτων Ανθεκτική χαμηλή συντήρηση

Περιγραφή

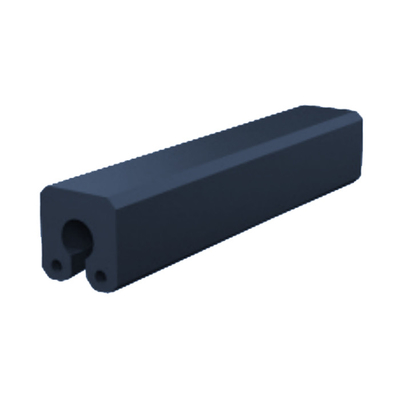

Σχεδιασμένο για περιοχές υψηλού αντίκτυπου, όπως τα πολυσύχναστα λιμάνια και οι βαριές αποβάθρες, αυτός ο κυλινδρικός θαλάσσιος προστατευτικός φτέρνας παρέχει ανώτερη προστασία για μεγάλα εμπορικά πλοία, δεξαμενόπλοια και ρυμουλκείς.Κατασκευασμένα από ανθεκτικό στην φθορά καουτσούκ με ενισχυμένους πυρήνες, παρέχει εξαιρετική απορρόφηση ενέργειας με ελάχιστη δύναμη αντίδρασης.μπορεί να τοποθετηθεί οριζόντια για συνεχή προστασία ή κάθετα για ευέλικτη αγκυροβολίαΤο στερεό καουτσούκ του φτέρνου εξασφαλίζει μακρά διάρκεια ζωής με εξαιρετική αντοχή στο αλμυρό νερό, τις υπεριώδεις ακτίνες και το όζον.παρέχει ανθεκτική και αποτελεσματική προστασία, ελαχιστοποιώντας ταυτόχρονα το χρόνο στάσης συντήρησης.

Προδιαγραφές

| Ονομασία του προϊόντος |

Κυλινδρικές θαλάσσιες φτερούγες |

| Υλικό |

Φυσικό καουτσούκ, NBR, EPDM |

| Τύπος |

ΠΡΑΝΚ2002, HGT2866-2016 |

| Μέγεθος |

ID: 75-1000mm, OD: 150-2000mm ή προσαρμοσμένο |

| Χρώμα |

Κόκκινο, Κίτρινο, Μπλε, Μαύρο, Λευκό κλπ. |

| Σκληρότητα |

55 Ακτή Α |

| Υπηρεσία επεξεργασίας |

Σχηματισμός, Κόψιμο |

| Δυνατότητα τράβηξης |

≥ 18 MPA |

| Επεμήκυνση κατά τη διάσπαση |

≥ 400% |

| Ειδικότητα |

Φιλικό προς το περιβάλλον |

| Εφαρμογή |

Αποβάθρα, λιμάνι, προβλήτα, πλοίο |

| Πλεονέκτημα |

Υψηλή ανθεκτικότητα |

| Ποιότητα |

Μακροχρόνια Ζωή |

| Λειτουργία |

Απορρόφηση σοκ |

| Υπηρεσία |

Εξυπηρέτηση CustomOEM ODM |

| Συσκευή |

Εσωτερική συσκευασία: Α. Διαχωρισμένα, κάθε κομμάτι με ετικέτα φροντίδας + Τάμπαλιν

Β. Παρτίδα, κάθε κομμάτι συσκευάζεται σε διαφανή πλαστική ταινία

Εξωτερική συσκευασία: Τσαγιέρα ή πλαστική ταινία

|

| Σχήμα |

Διάρκεια |

Εσωτερική διάμετρος |

Εξωτερική διάμετρος |

| Κύλινδρο |

[μμ] |

[μμ] |

[μμ] |

| HM-CMF150 |

Προσαρμοσμένο μήκος |

75 |

150 |

| HM-CMF200 |

100 |

200 |

| HM-CMF250 |

125 |

250 |

| HM-CMF300 |

150 |

300 |

| HM-CMF400 |

200 |

400 |

| HM-CMF500 |

250 |

500 |

| HM-CMF600 |

300 |

600 |

| HM-CMF700 |

350 |

700 |

| HM-CMF800 |

400 |

800 |

| HM-CMF900 |

450 |

900 |

| HM-CMF1000 |

500 |

1000 |

| HM-CMF1100 |

550 |

1100 |

| HM-CMF1200 |

600 |

1200 |

| HM-CMF1400 |

700 |

1400 |

| HM-CMF1600 |

800 |

1600 |

| HM-CMF700 |

850 |

1700 |

| HM-CMF800 |

900 |

1800 |

| HM-CMF1900 |

950 |

1900 |

| HM-CMF2000 |

1000 |

2000 |

Χαρακτηριστικά

Δεν απαιτείται εσωτερική πίεση

Η κατασκευή από στερεό καουτσούκ εξαλείφει τον κίνδυνο αποπληθωρισμού ή διαρροής αέρα, προσφέροντας λειτουργία χωρίς συντήρηση.

Υλικά φιλικά προς το περιβάλλον

Κατασκευασμένο από μη τοξικές, ανακυκλώσιμες συνθέσεις καουτσούκ που συμμορφώνονται με τα διεθνή πρότυπα περιβάλλοντος και ασφάλειας.

Μειωμένα σημεία πίεσης στο κύτος

Το στρογγυλό σχήμα κατανέμει την ενέργεια ομοιόμορφα, ελαχιστοποιώντας τα συγκεντρωμένα σημεία άγχους στις επιφάνειες των αγγείων.

Μικρές απαιτήσεις συντήρησης

Δεν απαιτεί συχνές επιθεωρήσεις ή αντικατάσταση εξαρτημάτων, μειώνοντας σημαντικά το κόστος του κύκλου ζωής.

Εφαρμογές

●Τερματικοί σταθμοί πλοίων

●Λιμένες ρυμουλκούμενων

●Ράμπες Ro-Ro

Πλεονεκτήματα

Διαθέσιμη ευρεία γκάμα μεγεθών και διαμορφώσεων

Οι κυλινδρικοί θαλάσσιοι προστατευτικοί μας πτέρυγοι είναι διαθέσιμοι σε διαμέτρους από Ø300 mm έως Ø1200 mm, με μήκη έως και 3.000 mm ή περισσότερο.να ανταποκρίνεται σε διάφορες απαιτήσεις ενέργειας αγκυροβολίας και δομικά σχέδια.

Τελευταίο εξοπλισμό κατασκευής

Χρησιμοποιούμε προηγμένα μηχανήματα εξάντλησης, εξάντλησης και φόρμας για να διασφαλίσουμε τη συνέπεια του προϊόντος, την υψηλή αντοχή σύνδεσης και την απρόσκοπτη τελική επιφάνεια.Η επένδυσή μας στην αυτοματοποίηση και στην ακριβή εργαλεία αυξάνει την αποδοτικότητα της παραγωγής και μειώνει τα ελαττώματα.

Παγκόσμια εμπειρία εξαγωγής με αποδεδειγμένη απόδοση

Τα προϊόντα μας έχουν εξαχθεί σε περισσότερες από 50 χώρες και περιοχές, συμπεριλαμβανομένης της Νοτιοανατολικής Ασίας, της Μέσης Ανατολής, της Ευρώπης, της Νότιας Αμερικής και της Αφρικής.κυβερνητικές θαλάσσιες αρχές, και παγκόσμιους εργολάβους EPC, που παρέχουν προστατευτικά που εκτελούν αξιόπιστα στο πεδίο.

Μεγάλη παραγωγική ικανότητα για παραγγελίες χύδην

Με μια σύγχρονη μονάδα παραγωγής που καλύπτει χιλιάδες τετραγωνικά μέτρα, μπορούμε να παράγουμε μεγάλους όγκους φτερών σε σύντομο χρονικό διάστημα.διασφάλιση ότι πληρούνται οι επείγουσες προθεσμίες έργων και οι συνεχείς απαιτήσεις εφοδιασμού.

Γενικές ερωτήσεις

1Ποια είναι η διαφορά μεταξύ των στερεών και των κούφων κυλινδρικών φτέρνων;

Τα στερεά φτερά προσφέρουν υψηλότερη απορρόφηση ενέργειας και είναι κατάλληλα για εφαρμογές βαριάς φόρτωσης.

2- Μπορούν να παραδοθούν με εξαρτήματα;

Ναι, μπορούμε να προμηθεύσουμε τον εξοπλισμό τοποθέτησης όπως αλυσίδες, αγκάλια, βίδες άγκυρας και προστατευτικά μανίκια, εφόσον απαιτείται.

3Ποιο είναι το προθεσμία παραγωγής;

Ο χρόνος παράδοσης κυμαίνεται συνήθως από 15 έως 30 ημέρες ανάλογα με τον όγκο της παραγγελίας και την προσαρμογή.

4Μπορούν να εγκατασταθούν σε ψυχρά ή τροπικά κλίματα;

Τα συνθέματά μας είναι σχεδιασμένα να λειτουργούν τόσο στο κρύο όσο και στην ζέστη χωρίς να χάνουν την ελαστικότητα ή τη δύναμη τους.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!